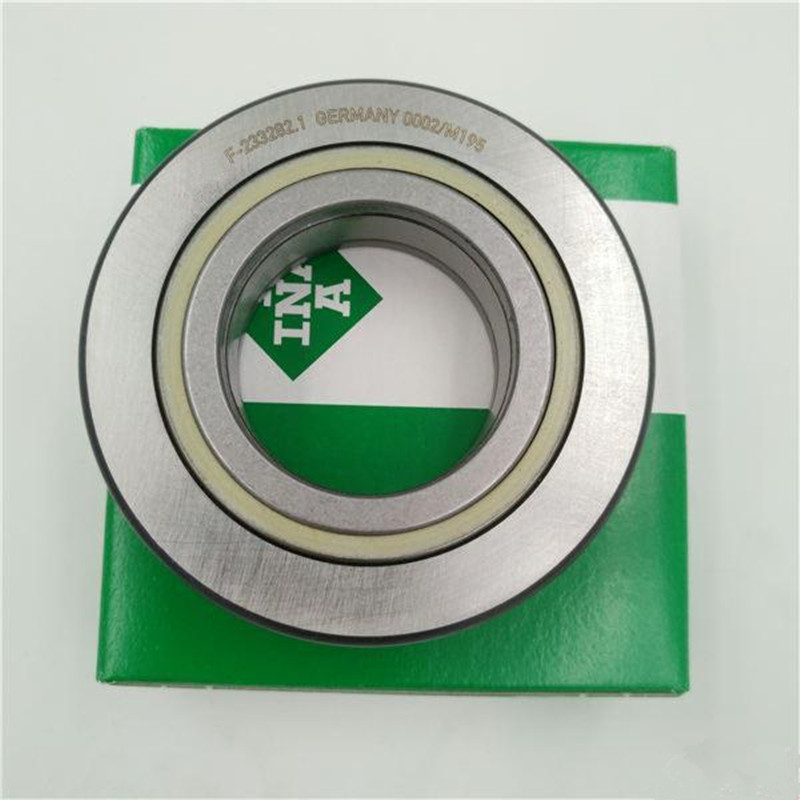

INA Heidelberger

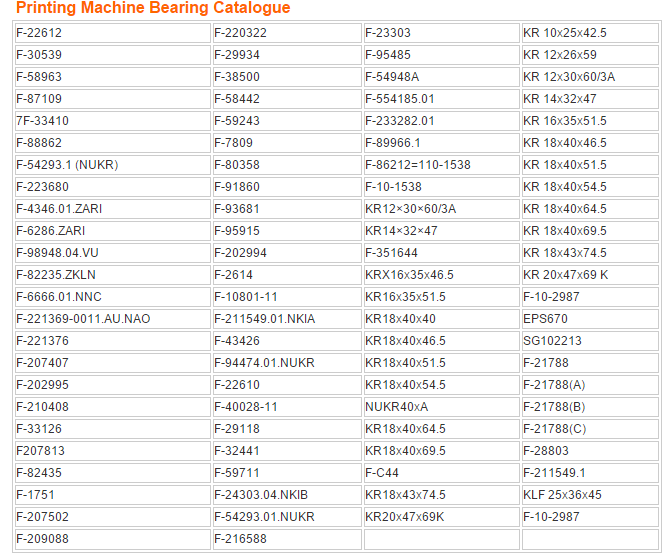

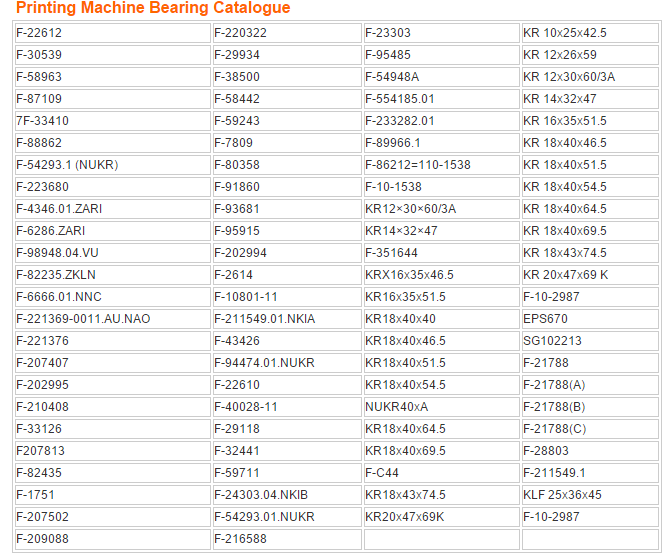

- Category: printing machine Bearing

- Description:The INA bearing company is a German INA bearing company under the company of Hoff flair It was founded in 194...

- Email:admin@jngybearing.com

- TEL:+86 15165026537

- Company:Ji'nan Guang Yue Pml Precision Mechanism Ltd Of China

Details

Contact Us

The INA bearing company is a German INA bearing company under the company of Hoff flair. It was founded in 1946 and is headquartered in Nuremberg, Germany. Since its establishment, the German INA bearings company has been committed to the innovation of products to meet the needs of customers and provide high quality assurance, making it the leading supplier of rolling bearings in the world and the recognized partner of the automobile manufacturer.

Company products

INA rolling bearings, INA sliding bearings, INA linear guide system, INA high precision products, INA engine parts and so on.

application

The products of German INA bearing include: agricultural machinery industry, construction industry, hydraulic and wind engineering industry, engineering machinery industry, machine tool and manufacturing machinery industry, material handling and packaging industry, port engineering industry, electric tool industry, gearbox industry, semi guide industry, pump and fan industry, industrial machine. Machinery and automation industry, rubber, plastics and chemical industry, textile industry, tractor industry, woodworking machinery industry and so on. In these industries, German INA bearings have been widely applied.

Development History

At present, INA bearing company has more than 30 production plants and more than thirty thousand employees. The wide range of products developed are rolling bearings, sliding bearings, linear guide systems, high precision products, and engine parts. INA bearing products include: machinery industry, construction industry, hydraulic and wind engineering industry, machine tool and manufacturing machinery industry, material processing and packaging industry, electric tool industry, gearbox industry, semiconductor industry, pump and fan industry, industrial robot and automation industry, rubber, plastic and INA bearings, such as chemical industry, textile industry, tractor industry, are an international group company, headquartered in Nuremberg, Germany, founded in 1946. Since its establishment, the company has become the world leader in the field of needle roller bearings, and it has expanded rapidly from the field of needle roller bearings to a wide range of products.

The design of adjacent structures requires that the bearing of the printer is a very robust mechanical element, which requires a high precision in the surrounding structure, and the modern processing equipment can be achieved completely. The most important requirement for the surrounding structure is the high precision axle diameter and the precision processing wall panel hole. Usually, the journal must be grinded, the wall hole should be fined, and honed when necessary, figure 1. Internal radial travel of cylindrical bore bearing

The radial clearance of the bearing inside the gap cylindrical inner hole printer is specially designed according to the specific application. The swing bearings in the three and four bearings are zero clearance or light pre tightening, and have been set up when the bearing is out of factory. There is no need for customer adjustment. Schaeffler Group has advanced computing software aided design. In order to achieve the best function, all tolerances must be carefully determined.

The orientation of the bearing DML outer ring of the printing machine bearing is very simple because it does not bear axial force in the work. The eccentric middle ring and outer ring of the three and four bearings are positioned axially through the shoulder and the retaining ring of the bearing. Therefore, for bearing units DML3E, DML3D and DMLD, axial positioning is not required through peripheral structures. Generally, the eccentric ring can be fixed to the wallboard through the peripheral parts, which can be enough to achieve axial positioning. Thirty-seventh pages, Fig. 1. If a roller bearing is used at both ends of the roller bearing, another roller bearing will be required to bear axial force. Because the axial force of the printing machine is usually very low, the economic standard bearings can meet the requirements. Proven reliable types include two angular contact ball bearings with zero clearance, two way thrust needle bearings or two way thrust cylindrical roller bearings.

Tolerance of shaft and bearing hole is minimum for tolerance of bearing clearance, and tolerance of cylindrical shaft diameter should be as small as possible. The prerequisite for optimization is that the tolerance level of the shaft should reach IT4. However, K5, which is the most commonly used shaft, can meet all requirements. For the conical shaft, the tolerance can be slightly larger due to the adjustment of the working clearance of the bearing. In this case, the coupling of the shaft is commonly used in js6. The tolerance of wallboard holes is usually transitional or tight fitting between printing machine bearings, wallboard holes and bearing outer rings. When the bearing unit DMLE or DML3D is used, if the external eccentricity needs to move in the work, a certain fit gap is needed. In order to minimize the possible deformation of the component, the tolerance zone should be as narrow as possible. This can be achieved by installing the bearing more appropriately into the wall panel orifice or by means of high precision machining, such as honing. In order to facilitate the selection and installation, the bearing of the printing press will be measured before leaving the factory, and the actual outer diameter is recorded on the bearing. For large volume production that often occurs in sheet fed offset presses, the more economical method is to design the outer diameter of the bearings in groups. The diameter tolerance of wallboard holes can be relatively large, which is very conducive to mass production.

The geometric tolerances of the bearing face should meet the requirements of the operation precision, stiffness, zero clearance, working temperature, and the requirements of excellent printing quality. Then the adjacent structures must meet certain minimum requirements. The geometric deviations of adjacent parts must be minimized. In order to achieve the required coordination, the matching surfaces of the shaft and bearing seat holes must conform to certain tolerances, figures 2, 3 and forty-second pages, and the table should pay attention to the requirements of the roughness of the bearings.

The accuracy level can see ISO basic tolerances that meet ISO 286. See page forty-third. The allowable geometric deviation must be determined according to the diameter of the shaft and the diameter of the seat hole. Example: the tolerance of shaft bearings is P5 and the shaft diameter is 90 mm. The tolerance values of the shaft are as follows. See table: roundness t = IT3 = 1/2 = 6. 1/2 = 3 m. The roughness of the mating surface of the bearing surface of the bearing must be matched with the tolerance grade of the bearing. The average roughness Ra should not be too large to ensure that the interference is limited. The shaft needs to be grinded, and the bearing hole must be fined. The design and safety guide in the product section also gives tolerances and allowable roughness for holes and shafts.

.png)