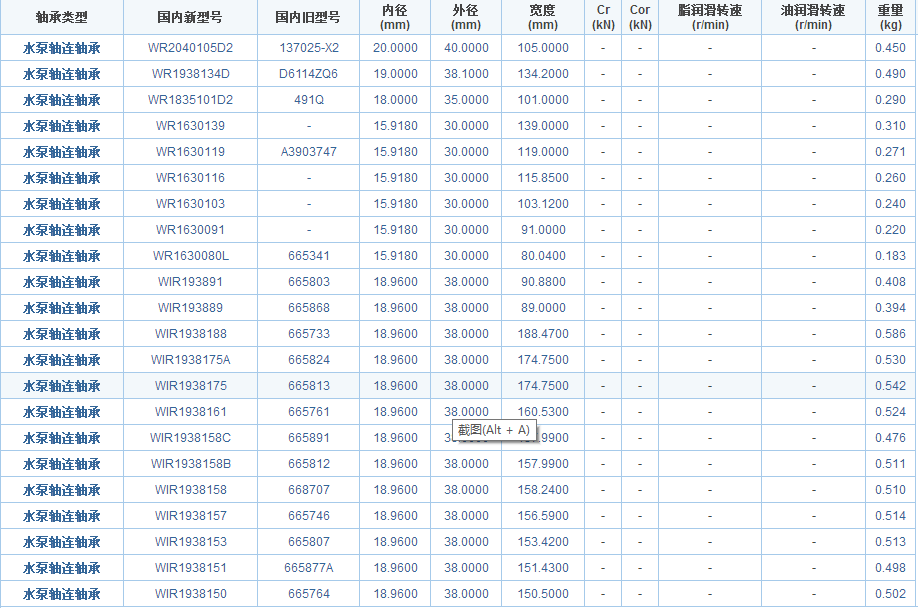

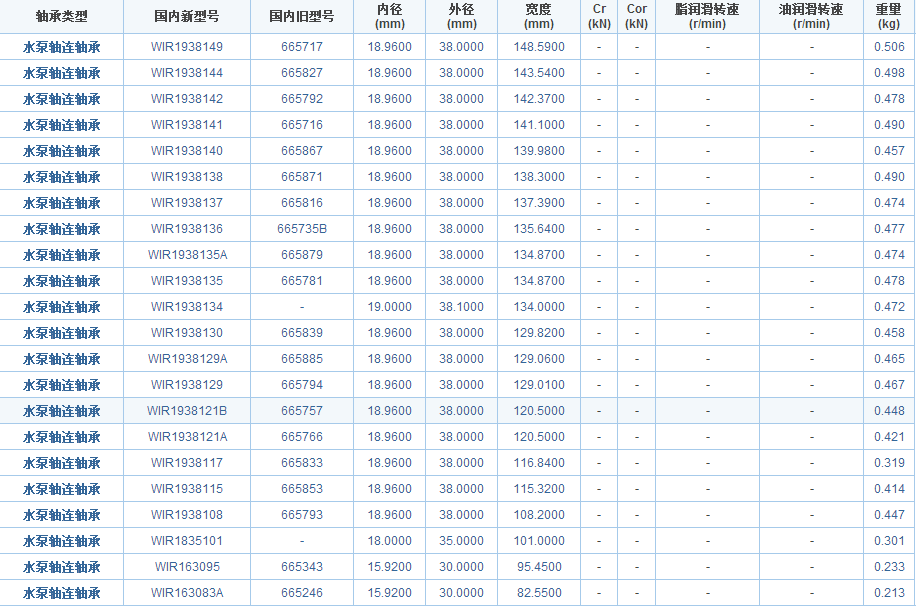

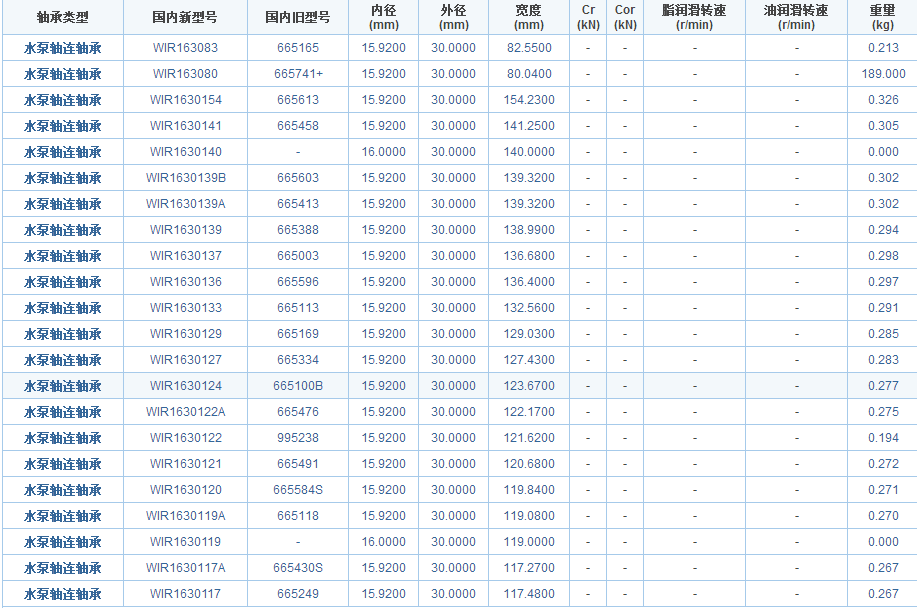

Water pump bearing

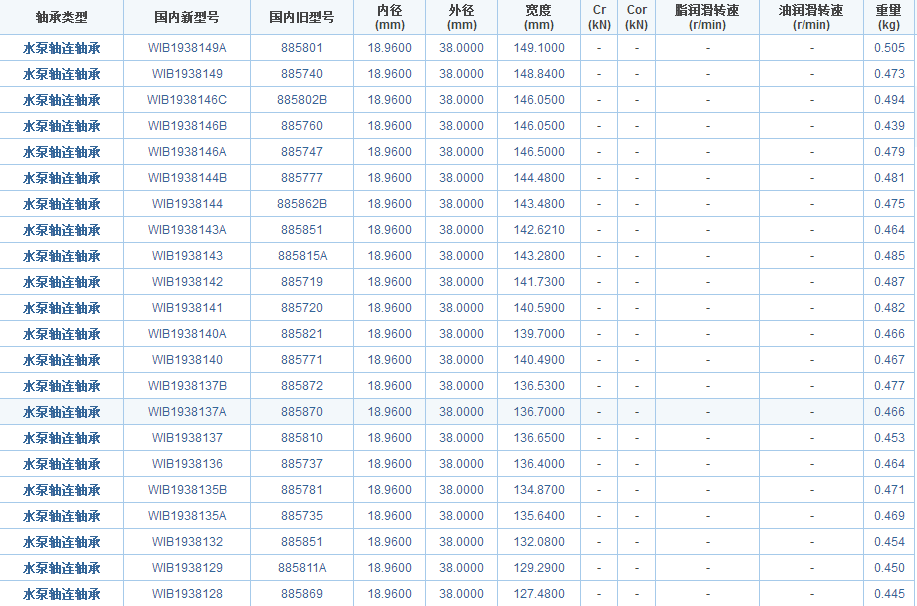

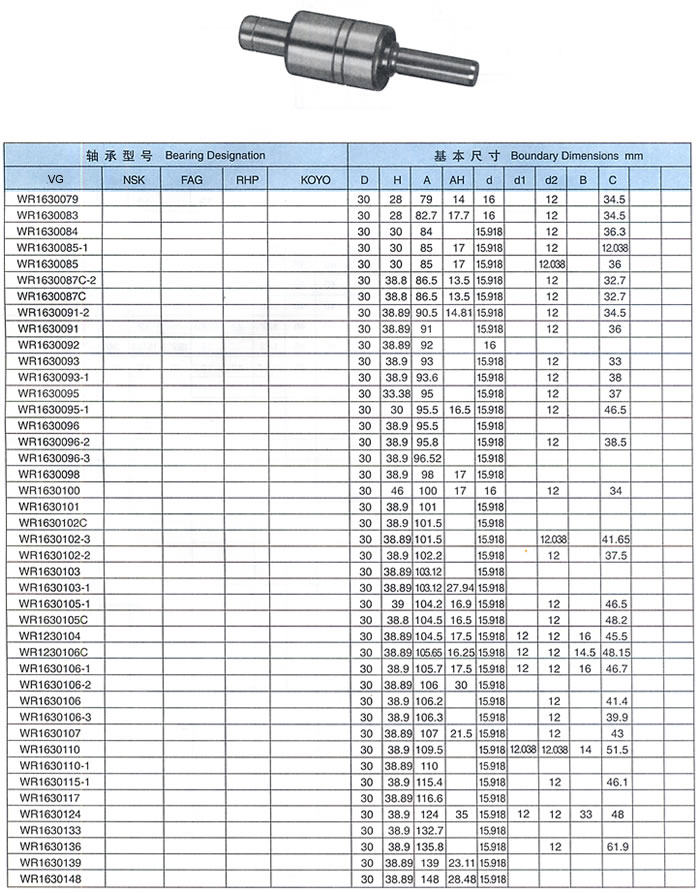

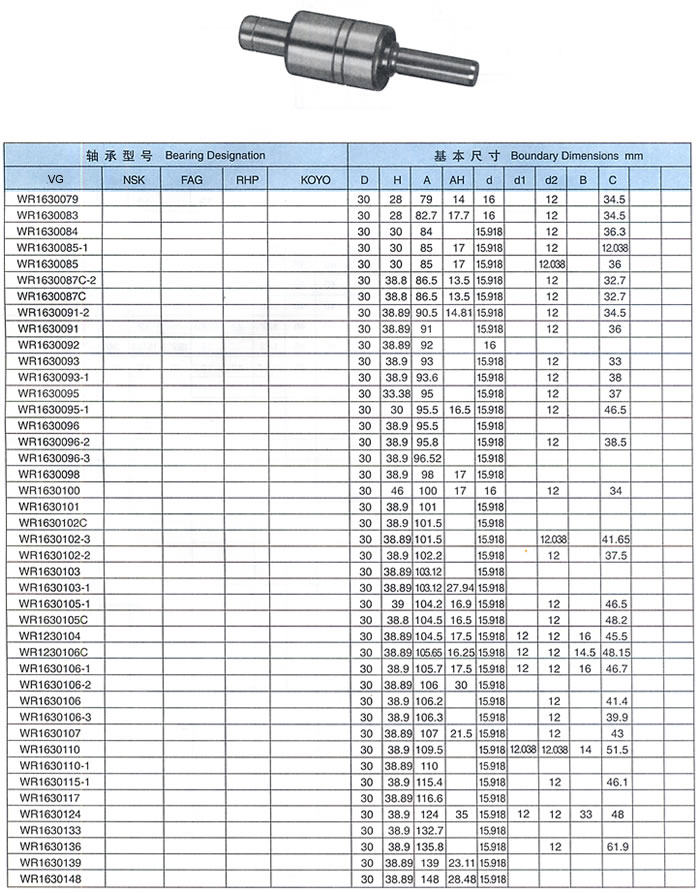

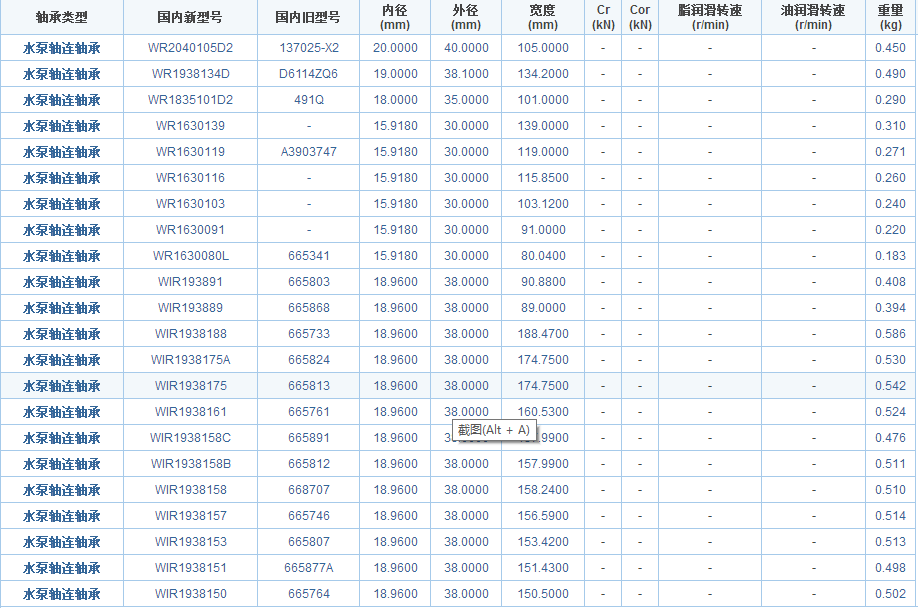

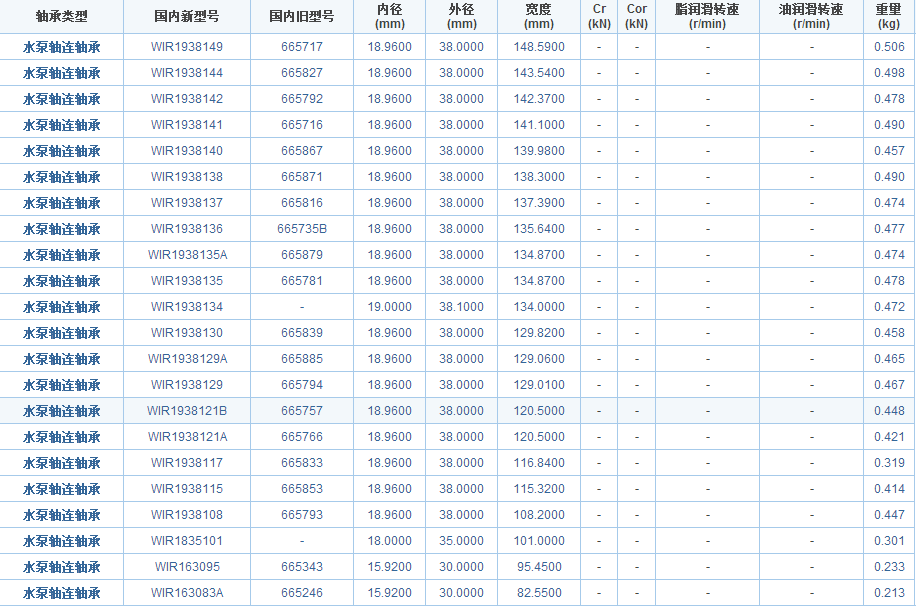

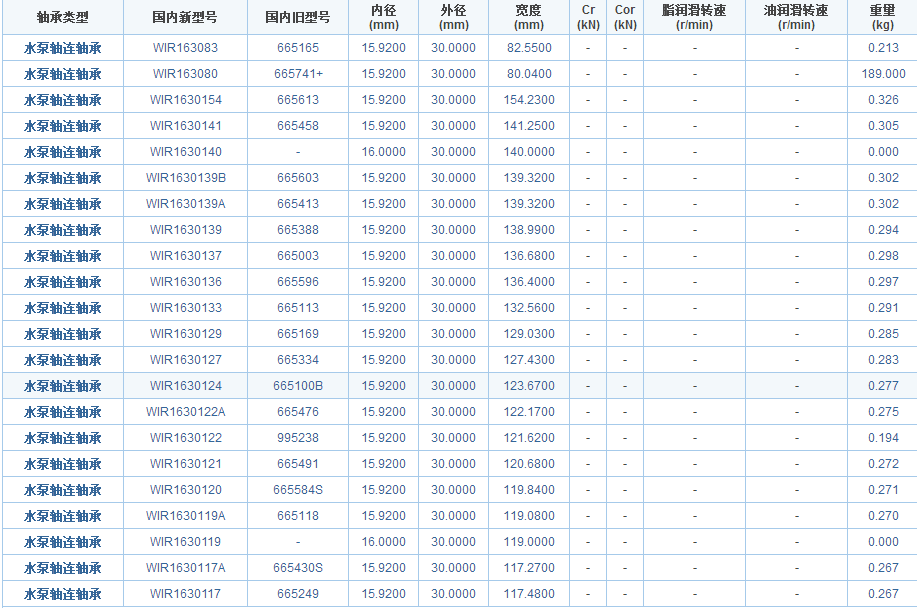

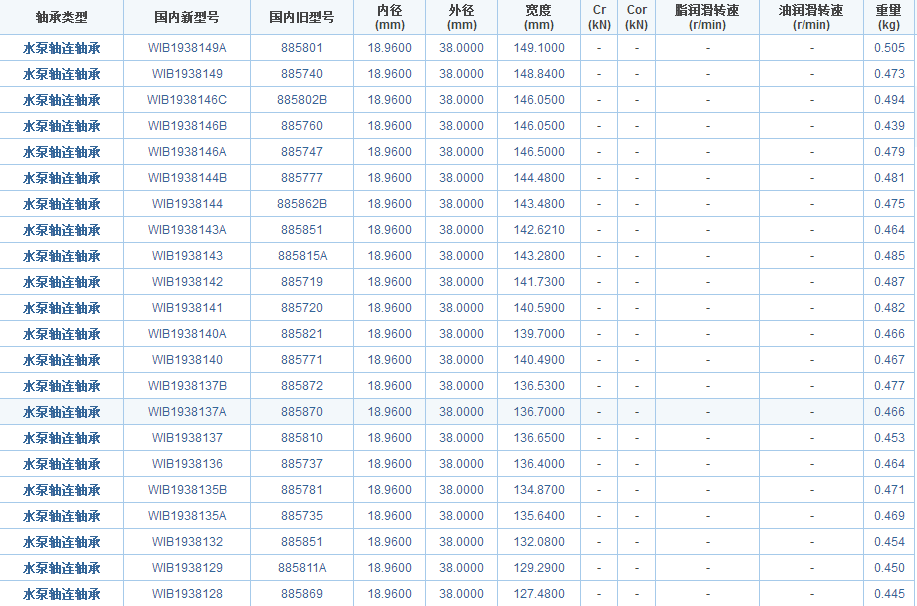

- Category: Water pump bearing

- Description:The shaft bearing of the automobile pump is a bearing The material of the cage is usually made of reinforced...

- Email:admin@jngybearing.com

- TEL:+86 15165026537

- Company:Ji'nan Guang Yue Pml Precision Mechanism Ltd Of China

Details

Contact Us

The shaft bearing of the automobile pump is a bearing. The material of the cage is usually made of reinforced nylon 66. The material of the sealing ring is generally used as the butadiene rubber. When the requirement is high, the fluoro rubber seal ring can also be used.

Conventional shaft bearings are made of steel (including shaft, outer ring, and ball roller) for high carbon chromium bearing steel (GCr15). Because of the high quality bearing steel smelting through the vacuum deoxidization, the electromagnetic stirring, the oxide content is less, can withstand the larger contact pressure stress and can bear a large high tensile stress at the same time, after heat treatment, the axle's raceway hardness is 58-62HRC. The hardness of the raceway is 60-64HRC, and the hardness of the ball and roller is 61-65HRC. When the shaft and outer ring are made of carburized bearing steel, the raceway hardness is 60-64HRC. The material of the cage material is usually reinforced nylon 66, and the sealing ring material usually adopts butadiene rubber. When the requirement is higher, fluorine rubber sealing ring can also be used.

Matters needing attention:

Prevention of assembly of foreign objects

When the inlet bearing is balanced on the rotor, it is very easy to enter the interior of the imported bearing when the balance is produced when the balance is moved, so it is better to balance the bearing before loading the bearing. In order to assemble, some oil or oil can be used to lubricate the imported bearing room, but it is often difficult for the operator to control the quantity. If oil or oil is kept in the imported bearing room, it is easy to enter the INA inlet bearing along the shaft of the inlet bearing of the pump shaft. The imported bearing chamber is best not to smear oil or grease if it is not coated.

Prevention of lacquer rust

The feature of lacquer rust is that the motor is mostly in sealed type motor. When the motor is assembled, the sound is very good, but after some time in the warehouse, the large dismantling pump shaft of the motor is seriously rusty. In the past, many manufacturers would consider the problem of imported bearings after our constant publicity. The motor factory has realized that the main problem is insulation paint. The main reason is that the acid substance volatilized by the insulating varnish is corrosive under certain temperature and humidity. The corrosion of the imported bearing groove lead to the damage of the INA inlet bearing. The problem can only be selected good insulating varnish and assembled after drying for a period of time.

Selection and control of tolerance of shaft and inlet bearing chamber

Pump shaft bearing bearings imported into the bearing should be flexible and no blockage. If obvious rotation is not flexible, it indicates that the shaft size is too large, and the tolerance should be reduced. For example, if the pump shaft is connected with an imported bearing, it has obvious "rustle" feeling when it is pressed into the shaft after being pressed into the shaft. It may be that the tolerance of the shaft is too large or the roundness of the shaft is not good. Therefore, the roundness must be controlled when controlling the tolerance of the shaft and the imported bearing chamber. Many domestic manufacturers only control the tolerance and do not control the roundness.

Assembly mode of imported bearings

Because imported bearings are high-precision products, pump shaft connection shaft, such as improper assembly, it is easy to cause damage to the bearing of the pump shaft and the bearing groove of INA, resulting in damage to the imported bearing. The imported bearing should have a special mold when it is assembled, and it can not be knocked at random. Only when the pressing shaft is loaded, can the small ring be forced? When assembly is required to use pressure or hydraulic pressure? In the pressure loading, the upper and lower reaches of the horizontal state if the tilt will cause the inlet bearing trench to be damaged by force, and make the inlet bearing lead.

.png)