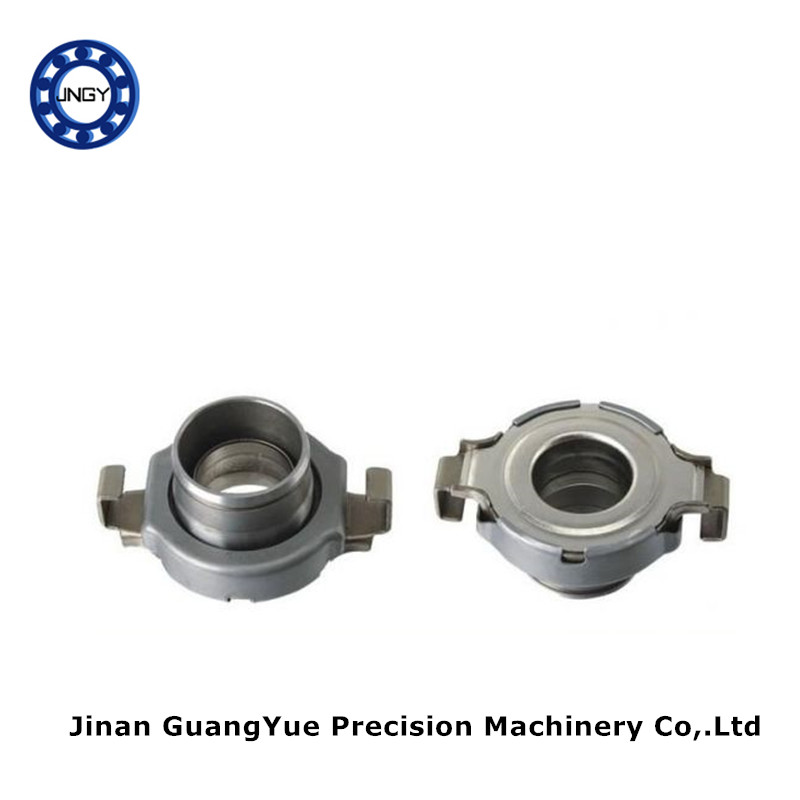

Clutch Bearing 1

- Category: Auto Bearing

- Description:When the clutch release bearing works, the clutch pedal& 39;s force will be transmitted to the clutch release bea...

- Email:admin@jngybearing.com

- TEL:+86 15165026537

- Company:Ji'nan Guang Yue Pml Precision Mechanism Ltd Of China

Details

Contact Us

When the clutch release bearing works, the clutch pedal's force will be transmitted to the clutch release bearing. The clutch bearing moves to the center of the clutch pressure plate, so that the pressure plate is pushed away from the clutch disc, so that the clutch disc is separated from the flywheel. When the clutch pedal is loosened, the spring pressure in the press disc will push the plate forward and press the clutch plate to separate the clutch and clutch bearings and complete a working cycle.

Fault cause editing

(1) overheating is caused by excessive working temperature. When a lot of drivers turn or decelerate, they often step on the clutch half and some of the rear feet are also placed on the clutch pedal. Some vehicles have too large free travel adjustment, which makes the clutch disconnected completely, in semi joint and semi separation state, which causes sliding friction between the friction disc and the flywheel, producing a large amount of friction. Heat transfer to the separation bearing, the shaft is heated to a certain temperature, the grease is melted or diluted, and the separation bearing temperature is further improved. When the temperature reaches a certain degree, the separation bearing is burned.

(2) the lack of grease and wear. The clutch separation bearing is lubricated by grease. In practice, it is easy for the repair personnel to neglect the lubrication problem of the separate bearing. When the installation is not installed, the lubricating grease is separated from the separate bearing, causing the clutch bearing to be short of oil. The wear volume of bearings without lubrication or less lubrication is often several times to several times that of bearings with lubrication and separation. As the wear increases, the temperature will also increase greatly, so that the bearing can be damaged more easily. Therefore, during the repair process, when installing the clutch, check the lubrication condition of the separate bearing, and timely add grease maintenance.

(3) the free travel is too small or overloaded. According to the requirements, the gap between the general clutch separation bearing and the separation lever is 2.5mm suitable, the free travel of the clutch pedal is 30 ~ 40mm, the free travel is too small or there is no free travel at all, which will make the separation lever and the separation bearing in the normal joint state. According to the fatigue failure principle, the longer the bearing working time, the more serious the damage is; the more times the load is, the easier the fatigue failure of the bearing is. Moreover, the longer the working time, the higher the temperature of the bearing, the easier it is to burn and reduce the service life of the separated bearing.

(4) whether the adjustment of the lever is smooth, whether the separation fork is deformed or not, whether the separation spring is good or not, has a great influence on the damage of the separation bearing. The separation and adjustment of unevenness, the deformation of the separation fork and the separation of the bearing spring will cause the separation bearing in the clutch work, the separation bearing is always in the working state, the temperature is higher and higher, the separation bearing is easy to burn, and the service life of the separation bearing is reduced.

.png)