SKF Thrust Roller Bearing

- Category: Thrust Roller Bearing

- Description:The thrust roller bearing is the same as the adjustable roller bearing The seat ring raceway surface is a sphe...

- Email:admin@jngybearing.com

- TEL:+86 15165026537

- Company:Ji'nan Guang Yue Pml Precision Mechanism Ltd Of China

Details

Contact Us

The thrust roller bearing is the same as the adjustable roller bearing. The seat ring raceway surface is a sphere centered on the center of the center axis of the bearing. This type of bearing roller is spherical. Therefore, it has automatic center function and is not sensitive to the coaxality and deflection of the axis.

Unlike other thrust bearings in the sample, the bearing capacity of this kind of bearing is very large, and can bear a number of radial loads while bearing the axial load, but the radial load should not exceed 55% of the axial load.

As long as the load P and P0 do not exceed 0.05C0 and the shaft circle rotates, the bearing allows the aligning angle listed in the following table.

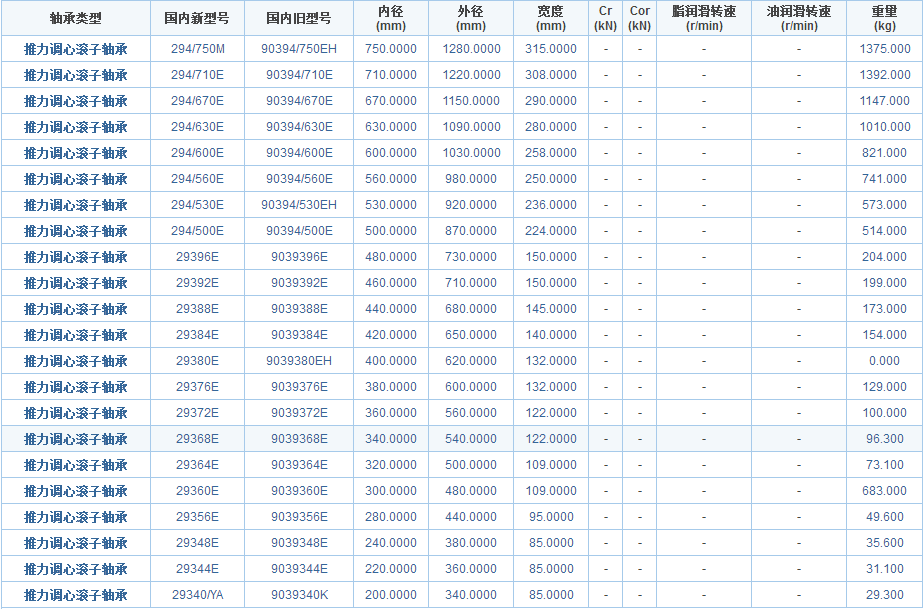

Bearing diameter series core angle bearing diameter series core angle 200 Series 1 degree ~1.5 degree 300 series 1.5 degree ~2 degree 400 series 2 degree ~3 degree is applicable to larger bearing, and the allowable core angle will be reduced when the load is increased.

Oil lubrication is generally used in use.

Thrust tapered roller bearings can only be subjected to uniaxial axial load, which can limit the uniaxial axial displacement of bearings, so it can be used for unidirectional axial positioning. Compared with the thrust cylindrical roller bearing, the bearing has the advantages of large load capacity and relatively small sliding speed, but the limit speed is low.

This type of bearings are mainly used in oil rigs, steel making machinery, hydraulic generators, vertical motors, propeller shaft for ships, tower cranes, extruders, etc.

Performance characteristics

1. The outer ring of the roller bearing is not fit with the hole of the bearing housing, and the coordination of the inner ring and the neck should not be too tight. It should be required to make the axial displacement of the nut in the installation of the nut when the nut is adjusted. Because interference fit of the spherical roller bearing can easily change the contact angle of the bearing, resulting in uneven load distribution of the bearing and causing high temperature rise. Therefore, the inner and outer ring of this kind of bearing, and the installation and coordination of the shaft neck and the bore of the bearing seat, should be the best with the thumb of both hands to just push the bearing into the neck and the hole of the shell.

2. For the installation of axial clearance of the roller bearing, the adjustment can be made by adjusting the nut on the neck of the shaft, adjusting the thread in the bore of the bearing seat, or using the pretightening spring. The size of the axial clearance is related to the arrangement of bearing installation, the distance between bearings, the material of the shaft and the bearing block, and can be determined according to the working conditions. For the adjustable roller bearing with high load and high speed, the effect of the temperature rise on the axial clearance must be considered when adjusting the clearance, which is to estimate the small amount of clearance caused by the temperature rise, that is to say, the axial clearance should be properly adjusted. For bearings with low speed and vibration, no clearance installation or pre load installation should be adopted. The purpose is to make the roller and raceway of the spherical roller bearings have good contact and uniform load distribution, so as to prevent roller and raceway from being damaged by vibration and impact. After adjustment, the size of the axial clearance is checked by micrometer. The method is to fix the dial on the fuselage or the bearing seat first, so that the dial of the dial is stuck to the smooth surface of the axis, and the axis is pushed along the axis, and the maximum swing of the needle is the value of the axial clearance.

.png)