koyo

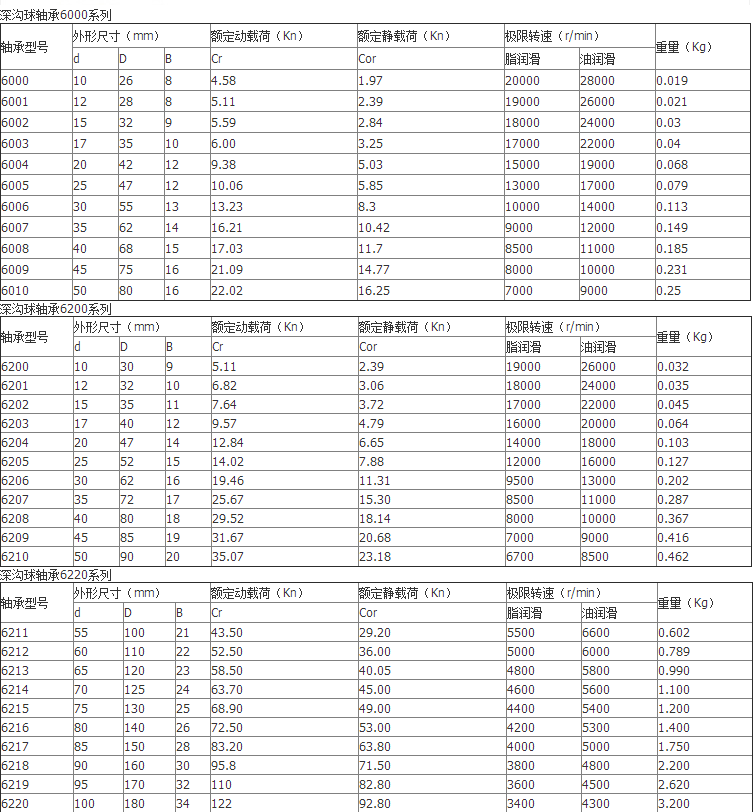

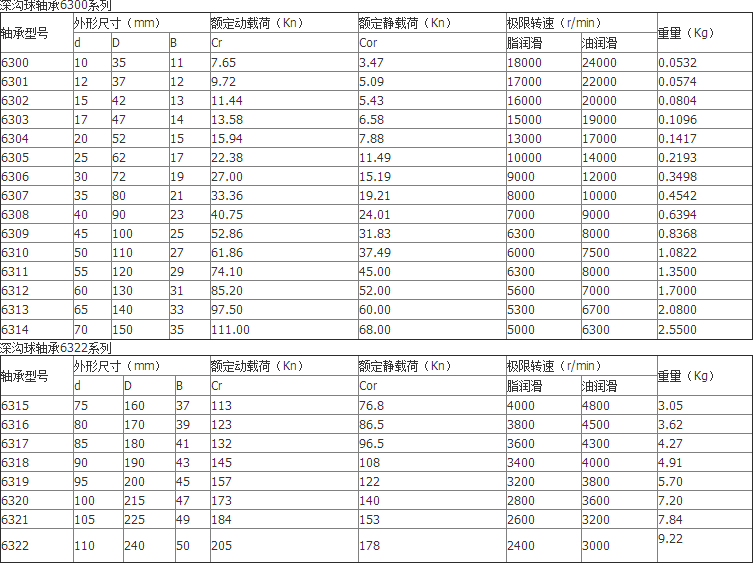

- Category: Deep Groove Ball

- Description:KOYO deep groove ball bearing main use:It is suitable for precision instruments, low noise motors, automobiles, mo...

- Email:admin@jngybearing.com

- TEL:+86 15165026537

- Company:Ji'nan Guang Yue Pml Precision Mechanism Ltd Of China

Details

Contact Us

KOYO deep groove ball bearing main use:

It is suitable for precision instruments, low noise motors, automobiles, motorcycles and general machinery. It is one of the most widely used bearings in the machinery industry.

KOYO deep groove ball bearing features:

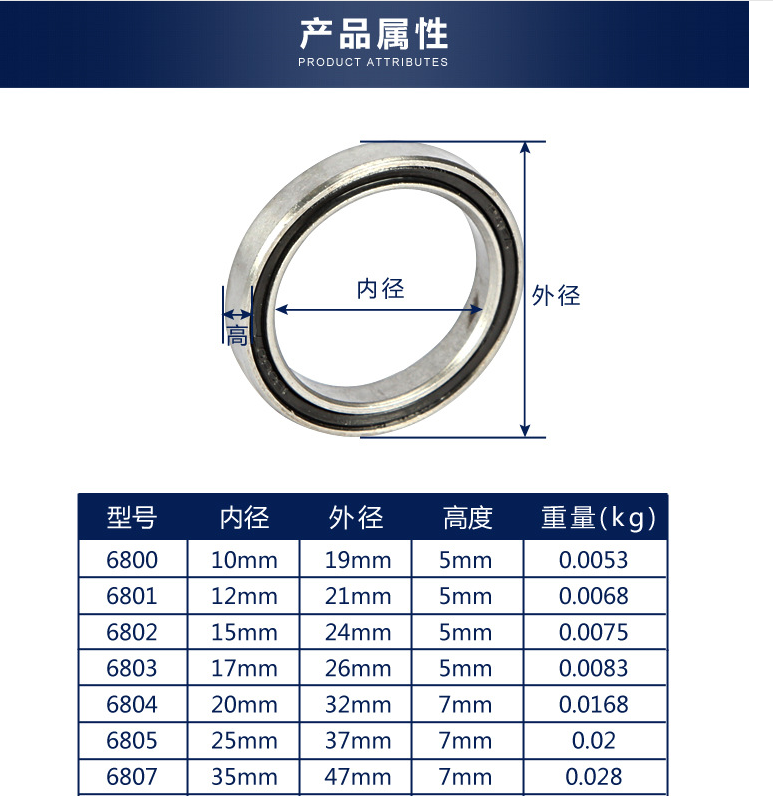

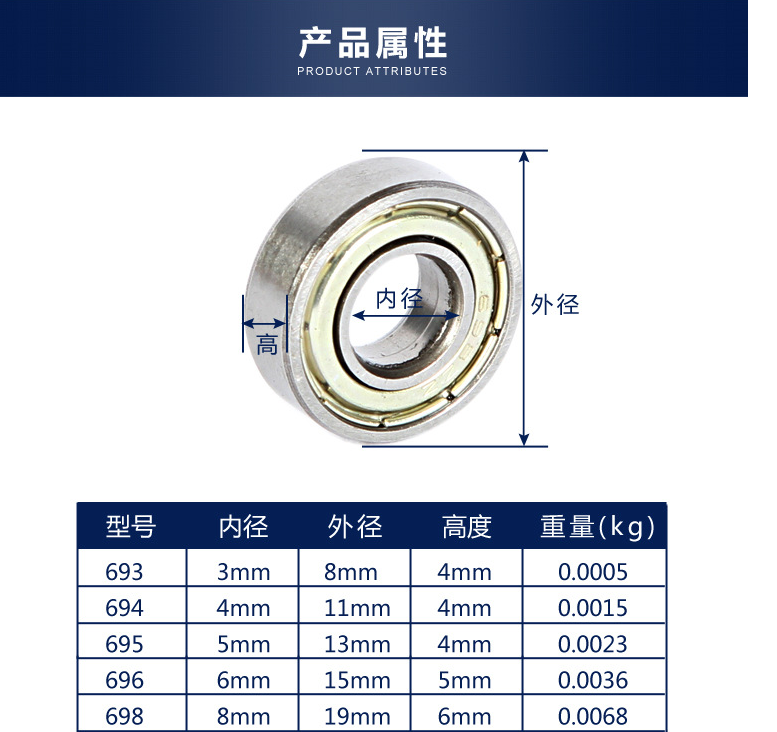

KOYO deep groove ball bearing is simple and easy to achieve higher manufacturing precision compared with other types, so it is easy to produce a series of large batch production, low manufacturing cost and very common use. When the larger radial clearance is chosen, the axial bearing capacity increases, and the contact angle is zero when subjected to pure radial force. When the axial force is applied, the contact angle is greater than zero. General use of stamping wave shaped cage, car made solid cage, and sometimes nylon frame.KOYO deep groove ball bearings except the basic type, there are various types of structure, such as: deep groove ball bearing with dust cover, deep groove ball bearing with rubber seal ring, deep groove ball bearing with stop slot, and large load capacity of KOY O deep groove ball bearings, KOYO double row deep groove ball bearings, but they all have the following common characteristics:

1. Each ring of the structural deep groove ball bearing has a continuous groove raceway with a cross section of about 1/3 of the circumference of the ball. It is mainly used to bear the radial load and can also bear a certain axial load.

2. When the radial clearance of bearing increases, it has the nature of angular contact ball bearing, and it can withstand alternating in two directions.

Axial load;

3, the friction is small, the speed is high.

4, simple structure, low manufacturing cost, easy to achieve higher manufacturing accuracy.

5, generally use the stamping wave cage, the inner diameter is larger than 200mm or the high speed running bearing, adopts vehicle body cage.

Installation and maintenance of KOYO deep groove ball bearing

KOYO deep groove ball bearing is the most representative rolling bearing with wide range of uses. It is suitable for high speed or even high speed operation, and is very durable, maintenance cost is low, and the operation cycle is long. But it is necessary for professional technicians to check and maintain regularly to ensure the safety, reliability, operation cycle and quality of operation.

Assembly of a KOYO deep groove ball bearing

The assembly of KOYO deep groove ball bearings requires that the assembly personnel have higher professional skills and strictly enforce the technical requirements and operating procedures during the assembly process.

Whether the bearing is good or bad or not will affect the precision, life and performance of the bearing. Therefore, please fully study the installation of the bearing. The bearing should be installed according to the following operating standards.

1 cleaning bearings and related parts (for grease lubricated bearings and bilateral oil seals or dustproof covers, seals need not be cleaned before installation).

2 check the size and finishing of the related parts.

3 installation method bearing should be fixed according to the bearing structure, size and the matching character of bearing parts. The pressure should be directly added to the end face of the tightly fitted ring, and the pressure should not be passed through the rolling body.

Operation maintenance and maintenance of two KOYO deep groove ball bearing

Reliable maintenance work is the main means to ensure the long cycle running of the bearing. The equipment should be checked and maintained by the professional and technical personnel for a period of time, mainly in the following aspects:

1 check the running temperature of the bearing, which is required below 65 degrees.

2 check the axial movement of the running parts. The main reason is whether the clearance of the bearing is in line with the requirement.

3 check whether there are pitting, corrosion, pits, cracks and other defects in bearing runways.

4 lubrication of lubricating oil or grease should be changed or added in time, but not too much. It requires 1/3 to 1/2 lube oil and 1/3 grease.

.png)